Diesel versus Gas Engine: Is There Any Difference on How an Exhaust System Works with Each Fuel Type

The diesel versus gas engine debate has been around forever. Both fuel sources require different types of engines because their fuel sources expend energy via two opposing methods. Meanwhile, turbochargers and fuel injection systems add complexity to the mechanical innards in the diesel compartment. These design factors explain engine performance differences and the need to roll up to the right pumps, but how do they affect exhaust system differences? In point of fact, are there any differences between them?

Compression Contrary Designs

Engine Compression characteristics are pushed to the limit in diesel applications. Temperatures rise higher, internal pressures are elevated, and gas velocities are accelerated. Conversely, more torque is generated by a diesel engine than a comparable gas model, so these lower RPMs will produce as much power as a fast-cycling gas engine.

Supplemented With Turbocharger Kits

The spark-less cylinders in a diesel engine rely on a compression ignition cycle, so a wide-bore exhaust system is required to handle the ignition pressure. Modern diesel vehicles also add a turbocharger, an engine augmentation solution that enhances overall power output. Turbocharger technology pre-compresses the air so that the fuel-air mix is enriched. Again, pressure and volumetric capacity parameters highlight a significant difference, so diesel exhaust systems do tend to assume a wide diameter profile.

Diesel Exhaust Systems

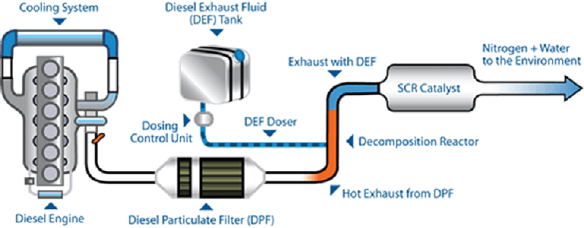

Modern diesel cars throw out more noxious fumes than a petrol-based (gasoline-fueled) car. The diesel exhaust isn’t as physically corrosive as the junk leaving a petrol engine, but it does more damage when enters the environment. In principle, a top-notch diesel system could use thinner materials in its construction because of this non-corrosive flow, but remember what we said about pressure and temperature. That’s right, the diesel tubes and chambers require armouring if they’re to handle these two internalized forces. As for the noxious output’s effects on the environment, the harmful emissions require additional sensors and smarter oxidizing solutions to remove this chemical soup.

There’s a spark plug assisting the gasoline engine. No such combustion assistance is at work in a diesel engine, which is why design balance is required in an aftermarket kit. The balance accommodates the high engine compression ratio by opening up the pipes. The other side of the solution, though, is a more active emissions control system, an asset that neutralizes diesel particulates, NOx (Nitrogen Oxide), and carbon monoxide. That catalyzing agent and the widened exhaust tubes then work efficiently so that the engine turbocharger operates at full capacity.

Trufit Exhaust

437 Warrigal Road

Moorabbin, VIC 3189,

Australia

Areas serviced: Melbourne

Tel: 03 9555 5688

Source: This Post “Diesel versus Gas Engine: Is There Any Difference on How an Exhaust System Works with Each Fuel Type” appeared first on”Trufit Exhaust“

Comments

Post a Comment